After the product is glazed, we put the product into the kiln for preliminary firing. Blowing the ceramic dust before firing can effectively improve the yield of the product. The dust on the surface of the product is removed, and it is not easy to cause the product to produce particles.

Firing is a very critical process in ceramic production. After being shaped and glazed, the semi-finished product can only undergo a series of physical and chemical reactions under the action of high temperature, and finally the apparent porosity is close to zero, in order to achieve a completely dense degree of porcelain. This process is called “firing”.

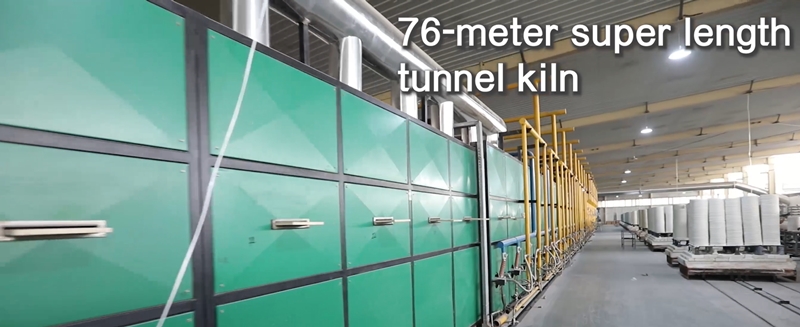

Because of the regional advantages, our factory has a larger site and equipment for firing products. We use tunnel kilns for production. The firing time is longer. The glaze, gloss, and thermal stability are better than those used in ordinary small factories Roller kiln is much better.

At the same time, tunnel kiln production is more continuous, the cycle is shorter, the output is larger, and the quality is higher. It works by the countercurrent principle, so the heat utilization rate is high, and the fuel is economical. Because the heat retention and waste heat utilization are good, the fuel is very economical. Compared with the inverted flame kiln, it can save about 50-60% of the fuel. quality improvement. The temperature of the three parts of the preheating zone, the firing zone and the cooling zone are often kept within a certain range, which makes it easy to grasp the firing law, so the quality is also better and the damage rate is less.

Post time: Jun-02-2021