In the ceramic tableware manufacturing process, the ceramic process design will affect the effect of the finished product to the greatest extent. Among the traditional ceramic decoration craftsmanship, color glaze products are the most commonly used design method. As one of the earliest ceramic crafts to be used, color glaze ceramics have been passed down in China for more than a thousand years because of its unique design effects. By adjusting the proportion of different pigments in the glaze, the ever-changing color effects can be adjusted. The glaze technology of contemporary color glaze is more diversified, the color glaze is more diversified, and the color glaze porcelain is more colorful. From monochromatic glaze to multi-color glaze and kiln glaze, more ceramic tableware products with different colors were born.

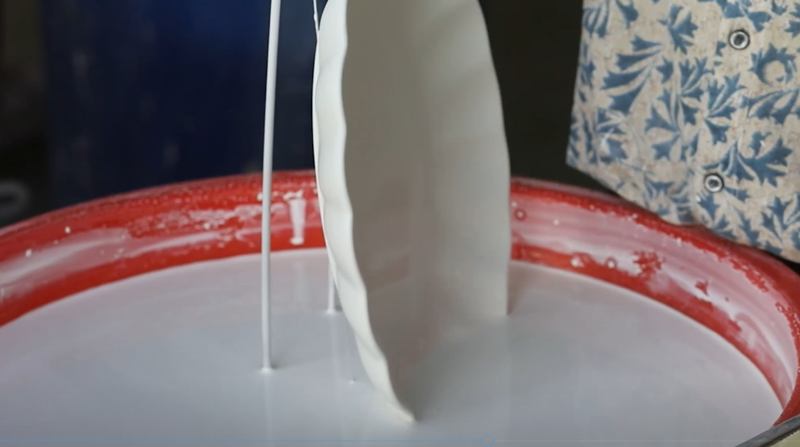

At the same time, different tableware appearance designs have different glazing methods. Usual single-color glaze tableware, we will use the method of dipping glaze to make. This is also the oldest method of glazing. Dipping glaze, also known as “dipping glaze”, is one of the most basic glazing techniques. The porcelain body is immersed in the glaze slurry and then taken out. The water absorption of the body is used to make the glaze slurry evenly adhere to the surface of the porcelain body. The thickness of the glaze layer is determined by the water absorption of the body, the concentration of the glaze slurry and the immersion time. Generally applicable to cups and bowls. In the process of glazing, the biggest influence on the future firing effect is the glazing time. Too short glazing time will cause the glaze to not be completely covered, and too long glazing time will cause the glaze to be too thick and form a finished product. Defects in the glaze layer.

In addition to the aforementioned glazing technique, after years of ceramic production development and technological innovation, the glaze spraying method emerged. The spray gun is used to spread the glaze evenly on the ceramic surface. The spray glaze process can apply different colors of glaze to the same product at the same time, which is suitable for more complex ceramic product designs.

Post time: May-27-2021